Introduction

North Yorkshire Moors Railway (NYMR) is a major heritage railway which runs through the heart of the North York Moors National Park. Widely regarded as one of the best-preserved heritage railways.

Grosmont home to the engine sheds and workshops, and the station facilities at Pickering house the Carriage & Wagon Department. Carrying out major overhauls and body repairs the workshop undertakes woodworking and joinery activities. This requires the installation of dust extraction to protect the work force and environment from airborne wood dust and shavings that are a result for the process.

Engaging with dust extraction specialists, Dust Control Environmental, North Yorkshire Moors Railway commissioned the installation of an ECO 30 for the efficient control of the process wood dust.

Project Requirements

The NYMR woodworking shop at Pickering station required, for environmental compliance and health and safety regulations, to collect and control particulates and dust at source. Specific machine points where dust was generated were the Planner Thicknesser, Cross Cut Saw, Band Saw and Disc and Belt Sander.

For space and safety, the dust control system would need to be positioned exterior to the facilities and so to comply with ATEX requirements. The footprint available for installation was somewhat limited.

The dust waste was to be collected in a receptacle that was big enough and easy enough to collect and dispose of the waste.

How DCE met the Requirements

The perfect dust control system to provide all the requirements for this specific project was the ECO 30 dust collector, manufactured and installed by Dust Control Environmental.

With its compact footprint, the ECO unit was easily accommodated on the available concrete pad outside the workshop. The dust filter housing is constructed from galvanised steel, providing robust weather resistance and unit longevity. Anti-static UltraFilter seamless polyester filter socks were installed to effectively and safely capture wood dust and fibres.

High-capacity waste hoppers feeding 2 waste collection drums with removable liners were incorporated into the dust extractor design.

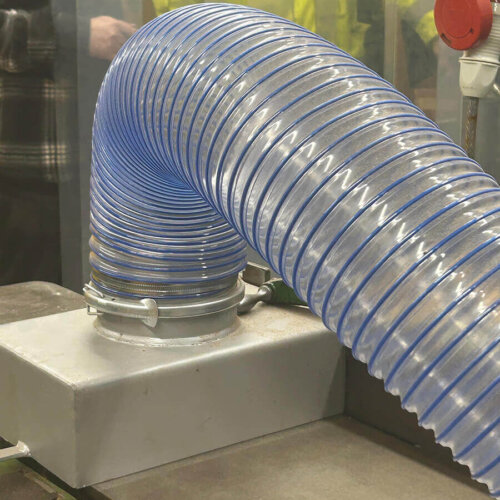

Inside the workshop, collection points on each of the specific machines were supplied with brand new extraction hoods each connected via quick clip, smooth bore ducting, installed to HSG 258 guidance and best practice. The connected ducting feeds back and out to the externally positioned ECO filter.

A DCE Zeph-Air duct flow indicator was installed and Commissioning was carried out by DCE’s certified P604 engineer. Training was given to those NYMR staff required to operate the ECO 30 Dust Filter.

The Benefits

- HSE & environmental compliance.

- Efficient dust collection at all operating points.

- Protection of workforce’s health.

- ATEX adaptations and the use of anti-static filter bags reduce the risk of explosion and fire.

- Durable, weatherproof materials provide unit longevity.

- Anti-static UltraFilter sock technology extends bag life, reducing maintenance and bag replacement requirements.

- Cleaner environment helps to extend life cycle of machines.

- Less time spent on housekeeping duties.

- Sustainable and easy waste collection, for re-use if required.

- Air flow indicator ensures compliant operation.

- Legal operation assured following full commissioning and training.

Customer Comment

Sam Cumbor of North Yorkshire Moors Railway commented DCE were excellent from initial site survey through project install right through to after install care. The design took into account all our requirements for the materials we use and was quickly installed. Setting up the maintenance inspections was also an easy process. ‘